UNUSUAL SEPTEMBER WEATHER PRESENTS SOLAR PANEL INSPECTION OPPORTUNITIES

We don’t usually complete many solar inspections in the month of September as it’s the start of autumn (the prime season for solar panel inspections of course is the long sunny days of summer). However, the unseasonable recent sunshine across the UK over the past few weeks have offered the opportunity for us to complete as many as 20 commercial solar panel inspections across the UK in four weeks, we managed to complete 5 in a 24-hour period alone!

Sun Irradiation

To complete an IEC compliant solar photovoltaic panel inspection, the requirement is for a minimum of 600 watts per square meter of solar irradiation. This is the reason that solar panel inspections are typically conducted from the late spring and throughout the summer in the UK. This year, we certainly cannot complain about the amount of sunshine we have had, in fact, it has been a record-breaking summer with temperatures exceeding 40°c for the first time.

Normally we do not get to plan many solar panel inspections in September but given this record-breaking year for sunshine and the continued great weather that we’ve all been enjoying, we decided to take on the task of planning 20 PV installation inspections from Manchester across to Huddersfield, down to Canterbury and to the Southwest as far as Yeovil for completition in a matter of a few weeks. Most of the photovoltaic panels were on Tesco roof tops, with others across commercial properties and solar ground installations.

Roof Access for Take Off and Landings

When solar installations are on commercial roofs, we look at conducting operations via accessing the roof directly where access is possible and safe to do so. This significantly reduces the risk to uninvolved people during the take-off and landing phases by creating an obvious natural separation. It is also much easier to ensure that the drone is always kept within visual line of sight (VLOS) while keeping altitude low enough to the solar panels to ensure IEC compliance.

When flights are conducted from ground level, there is always a need to stand further back to ensure VLOS when the drone is only going to be 30m above the modules. This in turn requires the drone flight-path to be further from the target, which introduces the possibilitiy of overflying uininvolved people and therefore introduces more risk mitigation requirements to ensure the safe flight.

When working from a roof it is important that all the necessary measures are taken to comply with the ‘Work at Height Regulations 2005’ and in some cases the use of compliant harnesses and other PPE. The choice of equipment is important as it is likely you will need to climb access ladders and access entry hatches, so equipment weight and mobility is key. In additon to the Working At Height legislation, our staff and drone pilots are trained in first aid and lone working requirements.

Flight Automation and Data Collection

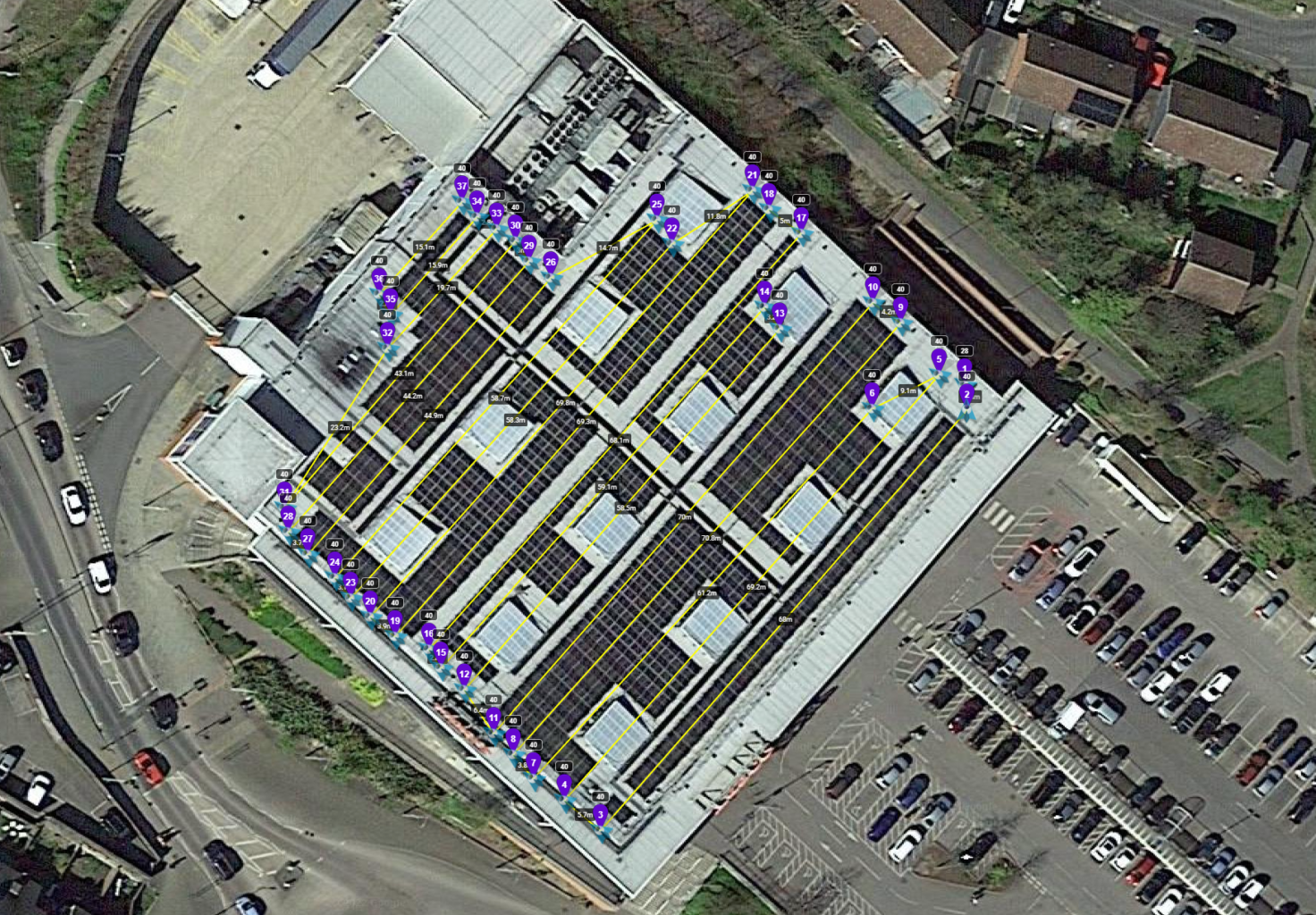

Professionally flown drones are extremely safe but one of the key roles of a pilot is to ensure that any risk, no matter how small, is minimised as much as possible while still achieving the flight objectives. When conducting flights, we use purpose-built flight automation applications to ensure that the drone movement is slow, methodical and time efficient to not only ensure the solar panel data is collected appropriately, but just as important, this approach minimises the risk of flying over the edges of the building which means that the potential for the drone to fall onto people at ground level, if a flight failure should occur, is at a minimum.

We use the software to conduct the flight at a constant speed and altitude, as well as ensuring no panels are missed. Flying manually offers the potential for flight errors and inconsistancies, particularly if the flight has to be stopped for a battery change.

We are Category 2 certified thermographers specialising in aerial thermal imaging, working under enhanced operating safety case (OSC) for reduced flight distances from uninvolved people. Coupled with our many years of inspection experience, we are perfectly placed to provide IEC compliant solar panel inspection across the UK for all types of ground and roof top installations.

#aerialthermography #IECSolarPanelInspection #PVInspections #PVPanelInspections #TescoSolarPanels #ThermalInspection #Thermalsolarsurvey #ThermographicPVinspection

https://www.dronemediaimaging.co.uk/20-solar-inspections-in-a-month/

Comments